STONE CRUSHERS , SCREENING EQUIPMENTS , CONVEYOR , SPARE PARTS

Salt And Sand Retention

In various industrial processes, retaining fine sand and eliminating excess salt and impurities are crucial steps to ensure high-quality output. Sand washers are machines designed specifically to separate unwanted materials from sand, improving the purity and usability of the end product. These washers play a key role in industries such as construction, glass production, and sand processing plants.

Benefits :

* Enhanced Product Quality: By efficiently removing salt, silt, and impurities, sand washers ensure a cleaner and more refined product.

*Cost Efficiency: The durability and minimal wear on parts make sand washers a cost-effective option in the long run.

*Increased Productivity: Sand washers allow for quick processing of materials, improving overall productivity in sand-related industries

CALL US RIGHT NOW TO PERSONAL CONSULTTATION OR PURCHASE ,

FILL FREE AND DO NOT HESITATE

Different types of sand washers are available depending on the specific needs of the operation:

1.Wheel Sand Washers: These are the most commonly used types, perfect for washing fine sand and removing light impurities. They are highly efficient and durable, providing consistent output with minimal maintenance.

2.Spiral Sand Washers: These washers are suitable for heavier materials, capable of separating sand from salt, soil, and other heavy impurities. Spiral washers ensure thorough cleaning and are ideal for high-capacity operations.

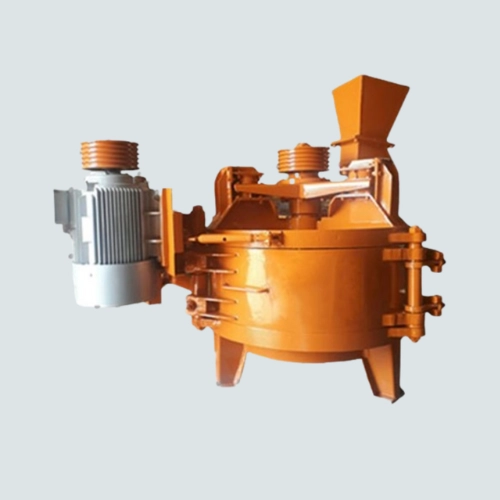

Sand Maker

Sand makers, also known as sand-making machines, are essential in industries that require finely crushed sand for construction and manufacturing. These machines are specifically designed to produce artificial sand and fine aggregates by crushing hard materials such as rocks and minerals. Sand makers are indispensable in industries such as construction, concrete production, and infrastructure development

ARIO MACHINE INDUSTRIAL GROUP with more than two decades experience in manufacturing and supplying stone crushers and spare parts

Benefits Of Rabbit Sand Makers :

1.High-Quality Final Product: Due to its unique design, the Rabbit Sand Maker can produce sand with precise and uniform grain size, which is essential in the production of concrete and other construction materials.

2.High Efficiency: This machine uses impact force to crush materials at high speed, increasing productivity while reducing production costs.

3.Wear Resistance: The internal components of the Rabbit Sand Maker are made from high-quality, wear-resistant materials, increasing the machine’s lifespan and reducing the need for frequent maintenance

Feeder

The feeder is one of the crucial pieces of equipment used in various industries, including mining, construction, and building material production. The primary function of the feeder is to feed and transfer raw materials to crushing and processing machines. By controlling the speed and volume of incoming materials, the feeder helps optimize production processes and prevent unwanted stoppages. Feeders come in various types, including vibrating feeders, chain feeders, and reciprocating feeders, each designed to meet specific needs

Vibrating Feeder :

This type of feeder uses vibrations to continuously and evenly guide materials to crushing machines. Vibrating feeders are widely used across many industries due to their simple structure and high efficiency. They are mainly used to transfer fine to medium-sized materials

Benefits :

Uniform operation, easy adjustment of speed and material volume, low energy consumption

Grizzly Screen Feeder:

This type of feeder is designed for heavy-duty use, capable of transferring large rocks to primary crushers. Grizzly bars are located in front of the feeder, allowing the adjustment of output size by changing the distance between the bars. Anti-wear plates are used in both the feeder’s pan and silo, ensuring durability and reducing damage to the main structure. Below the grizzly section, two types of material can be separated, and the passing material can be transferred to a separate conveyor belt

CALL US RIGHT NOW TO PERSONAL CONSULTTATION OR PURCHASE ,

FILL FREE AND DO NOT HESITATE

Screen

The vibrating screen, also known as a “Sereen,” is an essential piece of equipment in mining and construction industries. It is used to separate and categorize materials based on different sizes. This machine uses mesh screens of various sizes to divide incoming materials into different groups, separating larger particles from smaller ones

Vibrating Screens :

1.Durable and Strong Design: Vibrating screens are made from resistant metals like steel, allowing them to function effectively in tough mining and industrial conditions.

2.High Capacity: These machines can process large volumes of materials, making them ideal for large-scale mining projects.

3Adjustable Mesh Sizes: One of the important features is the ability to change or adjust the screen size to separate materials of different sizes.

4.Compatibility with Various Materials: Vibrating screens are capable of separating a wide range of materials, including stones, sand, minerals, and even chemicals and food products